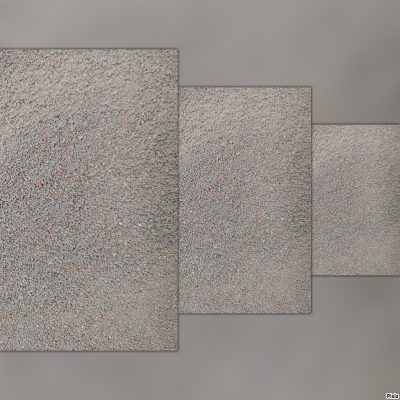

IIR Rubber Powder: special fine rubber free from heavy metals and PAH

IIR Powder is the product line of micronized rubber powders for applications where it needs to have a product stable to atmospheric agents, free of heavy metals, PAH.

Butyl rubber is produced by polymerization of about 98% of isobutylene with about 2% of isoprene.

It has excellent impermeability, and the long polyisobutylene segments of its polymer chain confer good elastic properties.

Application fields

Among the fields of use we report the possibility of being able to co-extrude it with other polyethylene and / or polypropylene based products to produce plastic compounds in which to give an elasticity.

IIR micronized rubber powder product environmental friendly

BR MIX 0006 it is of mixed colors micronized rubber powder from bromine isoprene and isobutylene and is made up of a high% polymer base. Check more on data sheet button above.

IIR or Copolymer of isobutylene and isoprene – Technical Notice

Butyl rubber was invented in 1937 as a copolymer derived from two distinct polymers: isoprene and isobutylene. It is modelled after natural rubber with very high molecular weight. In spite of a structure similar to that of natural rubber, it has different properties: for example, the raw form shows a lack of nerve and low tear resistance. In addition, compared to natural rubber, it needs higher doses of accelerators and activators, being devoid of the protein present in natural rubber.

Polyisoprene confers particular fluidity to compounds, a property that is particularly appreciated in moulding and specially calendering processes.

Unfortunately, due to its high cost, it has been replaced with natural rubber today. However, it is still used in friction compounds, specially when cut with polychloroprene, ensuring the prevention of overheating dangerous for burning.

An alternative version of butyl rubber called Halobutyl also exists, created by the addition of a small amount of chlorine or bromine to the main polymer chain. Halobutyl rubber can be vulcanized faster than normal butyl rubber and it is possible to use a smaller number of vulcanizing products in the process.

Fields of Application:

Butyl rubber dominates the market in the production of inner liners for tires and inner tubes. It is also used to replace natural rubber in other

cases such as pipes, pharmaceutical stoppers and sealants of any type. Durability and weather resistance are the primary reasons for its superiority over natural rubber. It is also used as protection from chemical and nuclear agents due to its low gas permeability.